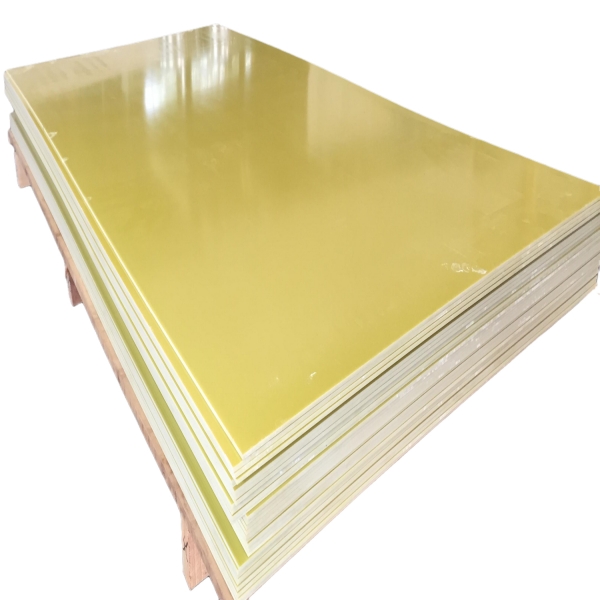

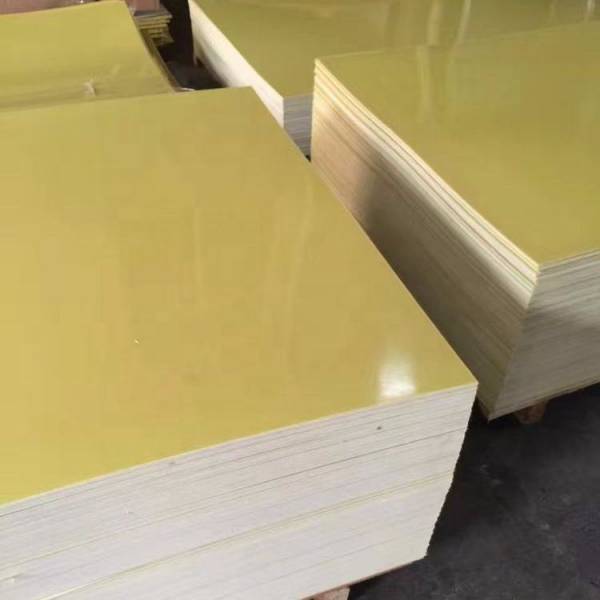

I-3240 Epoxy Phenolic Glass Cloth Base Rigid Laminated Sheet

Izidingo Zobuchwepheshe

1.1Ukubukeka:Ubuso beshidi kufanele bube bushelelezi futhi bube bushelelezi, bungabi namabhamuza omoya, imibimbi noma imifantu futhi bungabi nezinye iziphambeko ezincane njengokuklwebheka, ukufiphala, njll. Unqenqema lweshidi kufanele luhlanzeke futhi lungabi namabala noma imifantu. Umbala kufanele ufane kakhulu, kodwa amabala ambalwa ayavunyelwa.

1.2Ubukhulu kanye nokuvunyelweukubekezelelana

1.2.1 Ububanzi kanye nobude bamashidi

| Ububanzi Nobude (mm) | Ukubekezelelana (mm) |

| >970~3000 | +/-25 |

1.2.2 Ubukhulu obujwayelekile kanye nokubekezelelana

| Ubukhulu obujwayelekile (mm) | Ukubekezelelana (mm) | Ubukhulu obujwayelekile (mm) | Ukubekezelelana (mm) |

| 0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.12 +/-0.13 +/-0.16 +/-0.18 +/-0.20 +/-0.24 +/-0.28 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 80 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.95 +/-2.10 +/-2.30 +/-2.45 +/-2.50 +/-2.80 |

| Amazwana: Ngobukhulu obungebona obujwayelekile obungabhalwanga kuleli thebula, ukuphambuka kuzofana nobukhulu obukhulu obulandelayo. | |||

1.3Ukuphambuka Kokugoba

| Ubukhulu (mm) | Ukuphambuka Kokugoba | |

| 1000mm (Ubude bombusi) (mm) | 500mm (Ubude bombusi)(mm) | |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 | ≤2.5 ≤2.0 ≤1.5 |

1.4Ukucutshungulwa kwemishini:amashidi kumele angabi nemifantu, ama-demination kanye nezinsalela uma kusetshenziswa imishini efana nokusaha, ukubhoboza, ukufaka i-lathing kanye nokugaya.

1.5Izakhiwo zomzimba, zemishini kanye neze-elekthroniki

| Cha. | Izakhiwo | Iyunithi | Inani elijwayelekile | Inani elijwayelekile |

| 1 | Ubuningi | g/cm3 | 1.7~1.95 | 1.94 |

| 2 | Ukumuncwa kwamanzi (ishidi le-2mm) | mg | ≤20 | 5.7 |

| 3 | Amandla okugobeka, aqonde ngqo kuma-lamination | I-MPa | ≥340 | 417 |

| 4 | Amandla omthelela (i-Charpy, i-notch) | kJ/m2 | ≥30 | 50 |

| 5 | Isici sokushabalalisa i-dielectric 50Hz | --- | ≤5.5 | 4.48 |

| 6 | I-dielectric constant engu-50Hz | --- | ≤0.04 | 0.02 |

| 7 | Ukumelana nokushisa (Ngemva kwamahora angama-24 emanzini) | Ω | ≥5.0 x108 | 4.9 x109 |

| 8 | Amandla kagesi, aqonde ngqo kuma-lamination ku-transformer oil ku-90℃+/-2℃, ishidi elingu-1mm | kV/mm | ≥14.2 | 16.8 |

| 9 | I-Voltage Yokuqhekeka, ehambisana ne-laminations ku-oyili ye-transformer ku-90℃+/-2℃ | kV | ≥35 | 38 |

Ukupakisha, Ukuthutha kanye Nokugcina Izinto

Amashidi kufanele agcinwe endaweni lapho izinga lokushisa lingekho ngaphezu kuka-40℃, futhi abekwe ngokuvundlile epuletini lombhede elinokuphakama okungu-50mm noma ngaphezulu. Gcina kude nomlilo, ukushisa (imishini yokushisa) kanye nokukhanya kwelanga okuqondile. Isikhathi sokugcina samashidi siyizinyanga ezingu-18 kusukela ngosuku lokuphuma efektri. Uma isikhathi sokugcina singaphezu kwezinyanga ezingu-18, umkhiqizo ungasetshenziswa futhi ngemva kokuhlolwa ukuze uqinisekiswe.

Izimpawu kanye Nezinyathelo Zokuqapha Zokusebenzisa

Isivinini esiphezulu kanye nokujula okuncane kokusika kufanele kusetshenziswe lapho kucutshungulwa ngenxa yokushisa okubuthakathaka kwamashidi.

Ukushintshwa nokusikwa kwalo mkhiqizo kuzokhipha uthuli oluningi kanye nentuthu. Kufanele kuthathwe izinyathelo ezifanele ukuqinisekisa ukuthi amazinga othuli angaphakathi kwemingcele eyamukelekayo ngesikhathi sokusebenza. Kuyelulekwa ukuthi kungeniswe umoya wokukhipha umoya endaweni kanye nokusebenzisa imaski yothuli/yezinhlayiya.

Amashidi athola umswakama ngemva komshini, kunconywa ukuthi ambozwe nge-insulating vanish.

Imishini Yokukhiqiza

Iphakheji Yamashidi Agcotshwe Nge-Laminated