Ishidi lokuvikela elibunjiwe le-D370 SMC

Ishidi lokufaka elibunjiwe le-D370 SMC liwuhlobo lweshidi lokufaka eliqinile le-thermosetting. Lenziwe nge-SMC esikhumbeni ngaphansi kokushisa okuphezulu kanye nomfutho ophezulu. Linesitifiketi se-UL futhi liphumelele ukuhlolwa kwe-REACH kanye ne-RoHS, njll. Libizwa nangokuthi ishidi le-SMC, ibhodi lokufaka elibunjiwe le-SMC, njll.

I-SMC uhlobo lwenhlanganisela yokubumba ishidi equkethe i-fiber yengilazi eqiniswe nge-resin ye-polyester engagcwele, egcwele i-fire retardant kanye nezinye izinto zokugcwalisa.

Amashidi e-SMC anamandla aphezulu okusebenza, amandla e-dielectric, ukumelana okuhle komlilo, ukumelana nokulandelela, ukumelana ne-arc kanye ne-voltage ephakeme yokumelana, kanye nokumuncwa kwamanzi okuphansi, ukubekezelelana kobukhulu obuzinzile kanye nokugoba okuncane. Amashidi e-SMC asetshenziselwa ukwenza zonke izinhlobo zamabhodi okuvikela umswakama ngamagiya okushintsha ugesi aphezulu noma aphansi. Angasetshenziswa futhi ukucubungula ezinye izingxenye zesakhiwo sokuvikela umswakama.

Ubukhulu: 2.0mm ~ 60mm

Usayizi weshidi: 580mm * 850mm, 1000mm * 2000mm, 1300mm * 2000mm, 1500mm * 2000mm noma ezinye izinhlobo zosayizi ezixoxiswane ngazo

I-SMC

I-DMC

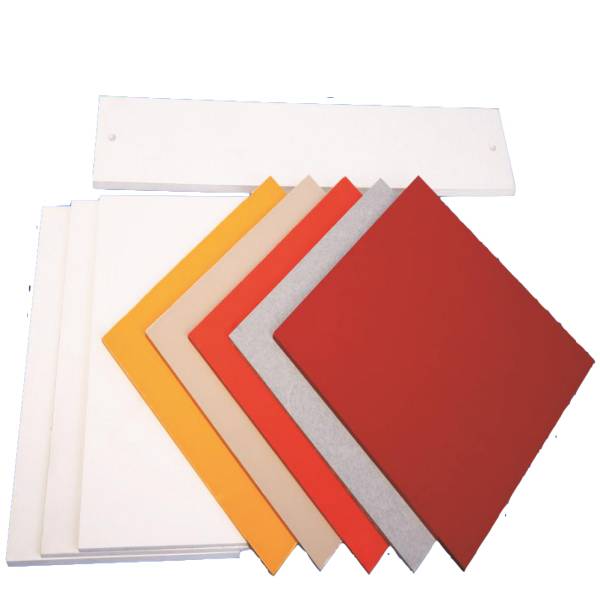

Amashidi e-SMC anombala ohlukile

Amashidi e-SMC

Izidingo Zobuchwepheshe

Ukubukeka

Ubuso bayo kufanele bube bushelelezi futhi bube bushelelezi, bungabi nama-blisters, ama-dents kanye nomonakalo obonakalayo wemishini. Umbala wobuso bayo kufanele ufane, ungabi nefayibha eveziwe esobala. Bungabi nokungcola okusobala, ukungcola kanye nezimbobo ezisobala. Bungabi noqhekeko kanye nokuqhekeka emaphethelweni ayo. Uma kukhona amaphutha ebusweni bomkhiqizo, angalungiswa. Umlotha omningi kakhulu kumele uhlanzwe.

I-bukuphela kokuphambukaIyunithi: mm

| Okukhethekile | Ubukhulu besimo | Ukujiya okujwayelekile S | Ukugoba ukuphambuka | Ukujiya okujwayelekile S | Ukugoba ukuphambuka | Ukujiya okujwayelekile S | Ukugoba ukuphambuka |

| Ishidi le-D370 SMC | Ubude bazo zonke izinhlangothi ≤500 | 3≤S<5 | ≤8 | 5≤S<10 | ≤5 | ≥10 | ≤4 |

| Ubude banoma yiluphi uhlangothi | 3≤S<5 | ≤12 | 5≤S<10 | ≤8 | ≥10 | ≤6 | |

| 500 kuya ku-1000 | |||||||

| Ubude banoma yiluphi uhlangothi ≥1000 | 3≤S<5 | ≤20 | 5≤S<10 | ≤15 | ≥10 | ≤10 |

Izidingo zokusebenza

Izakhiwo zomzimba, zemishini kanye nezikagesi zamashidi e-SMC

| Izakhiwo | Iyunithi | Inani elijwayelekile | Inani elijwayelekile | Indlela yokuhlola | ||

| Ubuningi | g/cm3 | 1.65—1.95 | 1.79 | GB/T1033.1-2008 | ||

| Ubulukhuni beBarcol | - | ≥ 55 | 60 | I-ASTM D2583-07 | ||

| Ukumuncwa kwamanzi, ubukhulu obungu-3mm | % | ≤0.2 | 0.13 | GB/T1034-2008 | ||

| Amandla okuguquguquka, aqonde ngqo kuma-lamination | Ubude obude | I-MPa | ≥170

| 243 | GB/T1449-2005 | |

| Ukuwela | ≥150 | 240 | ||||

| Amandla Omthelela, ahambisana nama-lamination (i-Charpy, engafakwanga) | I-KJ/m2 | ≥60 | 165 | GB/T1447-2005 | ||

| Amandla okudonsa | I-MPa | ≥55 | 143 | GB/T1447-2005 | ||

| Imodulus yokuqina kwe-Tensile | I-MPa | ≥9000 | 1.48 x 104 | |||

| Ukuncipha kokubumba | % | - | 0.07 | I-ISO2577:2007 | ||

| Amandla okucindezela (aqondile kuma-lamination) | I-MPa | ≥ 150 | 195 | GB/T1448-2005 | ||

| I-modulus yokucindezela | I-MPa | - | 8300 | |||

| Izinga lokushisa lokushintshashintsha kokushisa ngaphansi komthwalo (T)ff1.8) | ℃ | ≥190 | >240 | GB/T1634.2-2004 | ||

| I-Coefficient yokwandiswa kokushisa kwe-liner (20℃ --40℃) | 10-6/K | ≤18 | 16 | I-ISO11359-2-1999 | ||

| Amandla kagesi (ku-25# uwoyela we-transformer ku-23℃+/-2℃, ukuhlolwa kwesikhathi esifushane, Φ25mm/Φ75mm, i-electrode yesilinda) | I-KV/mm | ≥12 | 15.3 | GB/T1408.1-2006 | ||

| I-voltage yokuphuka (ihambisana ne-laminations, ku-25# transformer oil ku-23℃+/-2℃, ukuhlolwa kwesinyathelo ngesinyathelo kwamasekhondi angu-20, Φ130mm/Φ130mm, i-plate electrode) | KV | ≥25 | >100 | GB/T1408.1-2006 | ||

| Ukumelana nevolumu | Ω.m | ≥1.0 x 1012 | 3.9 x 1012 | GB/T1408.1-2006 | ||

| Ukumelana nomphezulu | Ω | ≥1.0 x 1012 | 2.6 x 1012 | |||

| Imvume ehlobene (1MHz) | - | ≤ 4.8 | 4.54 | GB/T1409-2006 | ||

| Isici sokushabalalisa i-dielectric (1MHz) | - | ≤ 0.06 | 9.05 x 10-3 | |||

| Ukumelana ne-Arc | s | ≥180 | 181 | GB/T1411-2002 | ||

| Ukumelana nokulandelela | I-CTI

| V | ≥600 | 600 I-overpass | GB/T1411-2002

| |

| I-PTI | ≥600 | 600 | ||||

| Ukumelana nokushisa | Esimweni esijwayelekile | Ω | ≥1.0 x 1013 | 3.0 x 1014 | GB/T10064-2006 | |

| Ngemva kwamahora angama-24 emanzini | ≥1.0 x 1012 | 2.5 x 1013 | ||||

| Ukuvutha | Ibanga | V-0 | V-0 | UL94-2010 | ||

| Inkomba ye-oxygen | ℃ | ≥ 22 | 32.1 | GB/T2406.1 | ||

| Ukuhlolwa kwentambo yokukhanya | ℃ | >850 | 960 | IEC61800-5-1 | ||

Melana ne-voltage

| Ubukhulu obujwayelekile (mm) | 3 | 4 | 5~6 | >6 |

| Imelana ne-voltage emoyeni umzuzu ongu-1 KV | ≥25 | ≥33 | ≥42 | >48 |

Ukuhlolwa, Uphawu, Ukupakisha kanye Nokugcina

1. Iqoqo ngalinye kufanele lihlolwe ngaphambi kokuthunyelwa.

2. Ngokwezidingo zamakhasimende, indlela yokuhlola ye-voltage yokumelana nayo ingaxoxiswana ngayo ngokweziqeshana noma izimo.

3. Ipakishwe ngebhokisi lekhadibhodi ephalethini. Isisindo sayo asidluli ku-500kg iphalethi ngayinye.

4. Amashidi kufanele agcinwe endaweni lapho izinga lokushisa lingekho ngaphezu kuka-40℃, futhi abekwe ngokuvundlile epuletini lombhede elinokuphakama okungu-50mm noma ngaphezulu. Gcina kude nomlilo, ukushisa (imishini yokushisa) kanye nokukhanya kwelanga okuqondile. Isikhathi sokugcina samashidi siyizinyanga ezingu-18 kusukela ngosuku lokuphuma efektri. Uma isikhathi sokugcina singaphezu kwezinyanga ezingu-18, umkhiqizo ungasetshenziswa futhi ngemva kokuhlolwa ukuze uqinisekiswe.

5. Abanye kufanele bavumelane nemigomo ye-GB/T1305-1985,Imithetho ejwayelekile ye ukuhlolwa, izimpawu, ukupakisha, ukuthuthwa kanye nokugcinwa kwezinto zokushisa ezivikela ukushisa.

Isitifiketi