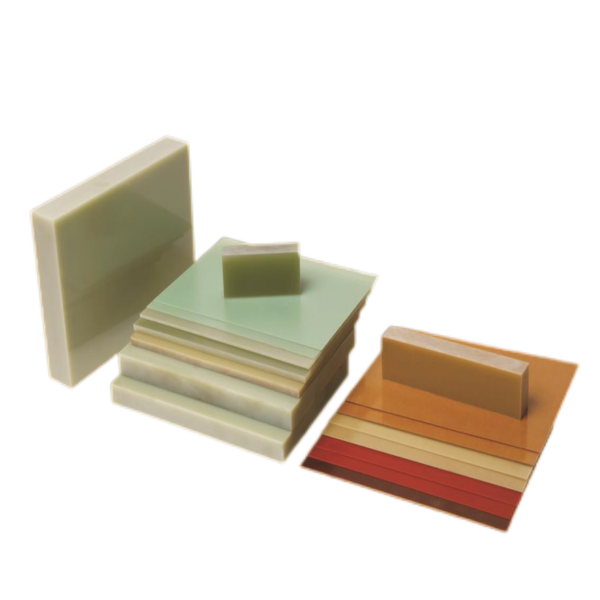

Indwangu Yengilazi Eshintshiwe ye-DF350A Diphenyl Ether Ishidi Eliqinile Elilaminethiwe

DF350AIndwangu yengilazi elukiwe efakwe i-resin ye-thermosetting ye-diphenyl ether eguquliwe, efakwe ngaphansi kokushisa okuphezulu kanye nengcindezi. Indwangu yengilazi elukiwe kufanele ingabi ne-alkali futhi iphathwe nge-KH560.

I-DF350A inokumelana okuhle nokushisa, inezakhiwo ezinhle kakhulu zemishini neze-dielectric, ifanele ukusetshenziswa kuma-motor kagesi ekilasi le-H noma imishini kagesi njengezingxenye noma izingxenye zesakhiwo sokushisa. Isetshenziswa ikakhulukazi kula ma-motor kagesi noma imishini kagesi edinga ukusebenza okuphezulu kwemishini ngaphansi kokucindezeleka kwesimo sokushisa.

Ubukhulu obutholakalayo:0.5mm ~ 200mm

Usayizi weshidi otholakalayo:

1500mm*3000mm、1220mm*3000mm、1020mm*2040mm,1220mm*2440mm、1000mm*2000mm kanye nezinye izinhlobo zosayizi ezixoxiswane ngazo.

Ubukhulu Obuqanjiwe Nokubekezelelana Okuvunyelwe (mm)

| Ukujiya okujwayelekile | Ukuphambuka | Ukujiya okujwayelekile | Ukuphambuka | Ukujiya okujwayelekile | Ukuphambuka |

| 0.5 | +/-0.15 | 3 | +/-0.37 | 16 | +/-1.12 |

| 0.6 | +/-0.15 | 4 | +/-0.45 | 20 | +/-1.30 |

| 0.8 | +/-0.18 | 5 | +/-0.52 | 25 | +/-1.50 |

| 1 | +/-0.18 | 6 | +/-0.60 | 30 | +/-1.70 |

| 1.2 | +/-0.21 | 8 | +/-0.72 | 35 | +/-1.95 |

| 1.5 | +/-0.25 | 10 | +/-0.94 | 40 | +/-2.10 |

| 2 | +/-0.30 | 12 | +/-0.94 | 45 | +/-2.45 |

| 2.5 | +/-0.33 | 14 | +/-1.02 | 50 | +/-2.60 |

Ukuphambuka Kokugoba (mm)

| Ubukhulu | Ukugoba ukuphambuka | |

| 1000 (Ubude bombusi) | 500 (Ubude bombusi) | |

| 3.0~6.0 | ≤10 | ≤2.5 |

| 6.1~8.0 | ≤8 | ≤2.0 |

| >8.0 | ≤6 | ≤1.5 |

Izakhiwo Zomzimba, Zomshini Nezokushisa Ugesi

| Cha. | Izakhiwo | Iyunithi | Inani elijwayelekile | Inani elijwayelekile | ||

| 1 | Ubuningi | g/cm3 | 1.70~1.95 | 1.9 | ||

| 2 | Amandla okugobeka, aqonde ngqo kuma-lamination (Ubude) | Esimweni esijwayelekile | I-MPa | ≥400 | 540 | |

| 180℃+/-2℃ | ≥200 | 400 | ||||

| 3 | Amandla omthelela (i-Charpy, i-notch, ubude) | kJ/m2 | ≥37 | 50 | ||

| 4 | Amandla okunamathela/isibopho | N | ≥5000 | 6900 | ||

| 5 | Ukumuncwa kwamanzi | mg | Bheka ithebula elilandelayo | 11.8 | ||

| 6 | Ukumelana nokushisa, okuhambisana nama-lamination | Esimweni esijwayelekile | I-MΩ | ≥1.0 x 106 | 5.3 x 107 | |

| Ngemva kwamahora angama-24 emanzini | ≥1.0 x 102 | 3.8 x 104 | ||||

| 7 | Isici sokushabalalisa i-dielectric 1MHz | -- | ≤0.05 | 1.03 x 10-2 | ||

| 8 | I-dielectric engaguquki engu-1MHz | -- | ≤5.5 | 4.7 | ||

| 9 | I-voltage yokuphuka, ehambisana nama-lamination (kuwoyela we-transformer ku-90℃+/-2℃) | kV | ≥30 | 35 | ||

| 10 | Amandla e-Dielectric, aqonde ngqo kuma-laminations (kuwoyela we-transformer ku-90℃+/-2℃), ishidi le-2mm | I-MV/m | ≥11.8 | 18 | ||

Ukumuncwa Kwamanzi

| Ubukhulu obumaphakathi bamasampula okuhlola (mm) | Ukumuncwa kwamanzi (mg) | Ubukhulu obumaphakathi bamasampula okuhlola (mm) | Ukumuncwa kwamanzi (mg) | Ubukhulu obumaphakathi bamasampula okuhlola (mm) | Ukumuncwa kwamanzi (mg) |

| 0.5 | ≤17 | 2.5 | ≤21 | 12 | ≤38 |

| 0.8 | ≤18 | 3.0 | ≤22 | 16 | ≤46 |

| 1.0 | ≤18 | 5.0 | ≤25 | 20 | ≤52 |

| 1.6 | ≤19 | 8.0 | ≤31 | 25 | ≤61 |

| 2.0 | ≤20 | 10 | ≤34 | Bheka Amazwi 2 | ≤73 |

| Amazwi:1) Uma isilinganiso esibaliwe sobukhulu obulinganisiwe siphakathi kobukhulu obubili okukhulunywe ngabo kuleli thebula, amanani azotholakala ngokuhlanganisa. Uma isilinganiso esilinganisiwe sobukhulu obulinganisiwe singaphansi kuka-0.5mm, ama-vales ngeke abe ngaphezu kuka-17mg. Uma isilinganiso esilinganisiwe sobukhulu obulinganisiwe singaphezu kuka-25mm, inani ngeke libe ngaphezu kuka-61mg.2) Uma ubukhulu obujwayelekile bungaphezu kuka-25mm, kufanele bufakwe ngomshini bube ngu-22.5mm ohlangothini olulodwa. Uhlangothi oluhlanganisiwe kufanele lube bushelelezi. | |||||

Ukupakisha Nokugcina Isitoreji

Amashidi kufanele agcinwe endaweni lapho izinga lokushisa lingekho ngaphezu kuka-40℃, futhi abekwe ngokuvundlile epuletini lombhede elinokuphakama okungu-50mm noma ngaphezulu.

Gcina kude nomlilo, ukushisa (imishini yokushisa) kanye nokukhanya kwelanga okuqondile. Isikhathi sokugcina amashidi siyizinyanga ezingu-18 kusukela ngosuku lokuphuma efektri. Uma isikhathi sokugcina singaphezu kwezinyanga ezingu-18, umkhiqizo ungasetshenziswa futhi ngemva kokuhlolwa ukuze uqinisekiswe.

Izimpawu kanye Nezinyathelo Zokuqapha Zokusebenzisa

Kufanele kusetshenziswe isivinini esiphezulu kanye nokujula okuncane kokusika lapho kucutshungulwa ngenxa yokushisa okubuthakathaka kwamashidi.

Ukushintshwa nokusikwa kwalo mkhiqizo kuzokhipha uthuli oluningi kanye nentuthu. Kufanele kuthathwe izinyathelo ezifanele ukuqinisekisa ukuthi amazinga othuli angaphakathi kwemingcele eyamukelekayo ngesikhathi sokusebenza. Kuyelulekwa ukuthi kungeniswe umoya wokukhipha umoya endaweni kanye nokusebenzisa imaski yothuli/yezinhlayiya ezifanele.

Amashidi athola umswakama ngemva komshini, kunconywa ukuthi ambozwe nge-insulating vanish.