Amashidi Aqinile Alaminethiweyo Endwangu Yengilazi Ye-Epoxy (amashidi e-EPGC)

I-EPGC series Epoxy Glass Cloth Rigid Laminated Sheet iqukethe indwangu yengilazi elukiwe efakwe i-epoxy thermoseting resin, efakwe ngaphansi kokushisa okuphezulu kanye nomfutho ophezulu. Indwangu yengilazi elukiwe kufanele ingabi ne-alkali futhi iphathwe yi-silane coupler. Amashidi e-EPGC serial afaka phakathi i-EPGC201 (NMEMA G10), i-EPGC202 (NEMA FR4), i-EPGC203 (NEMA G11), i-EPGC204 (NEMA FR5), i-EPGC306 kanye ne-EPGC308.

Amashidi e-EPGC (isigaba sokushisa: B~H), akhiqizwa ngokwe-IEC60893-3-2. Lawa mashidi anamandla amahle kakhulu okusebenza (izinga lokugcina amandla esimo sokushisa lingafinyelela ngaphezu kuka-50%) ngaphansi kokushisa okuphakathi noma isimo sokushisa, kanye nesakhiwo sikagesi esizinzile (ukumelana nokushisa ngemva kokucwiliswa kufinyelela ku-1012Ω) esimweni somswakama ophezulu. Futhi futhi ngokukhuthazela kwe-voltage ephezulu/ukumelana ne-voltage (ngaphezu kuka-35kV), okuhambisana ne-lamination. I-EPGC202, i-EPGC204 kanye ne-EPGC306 nazo zinezici ezinhle kakhulu zokuvimbela ilangabi. Amashidi nawo aphumelele ekutholakaleni kwezinto ezinobuthi neziyingozi (nge-RoHS Report).

Isetshenziswa njengezingxenye zesakhiwo sokushisa kuma-motor kagesi e-Class BH, imishini kagesi, enezidingo zokumelana nomlilo noma cha, noma ezinye izinhlelo zokusebenza.

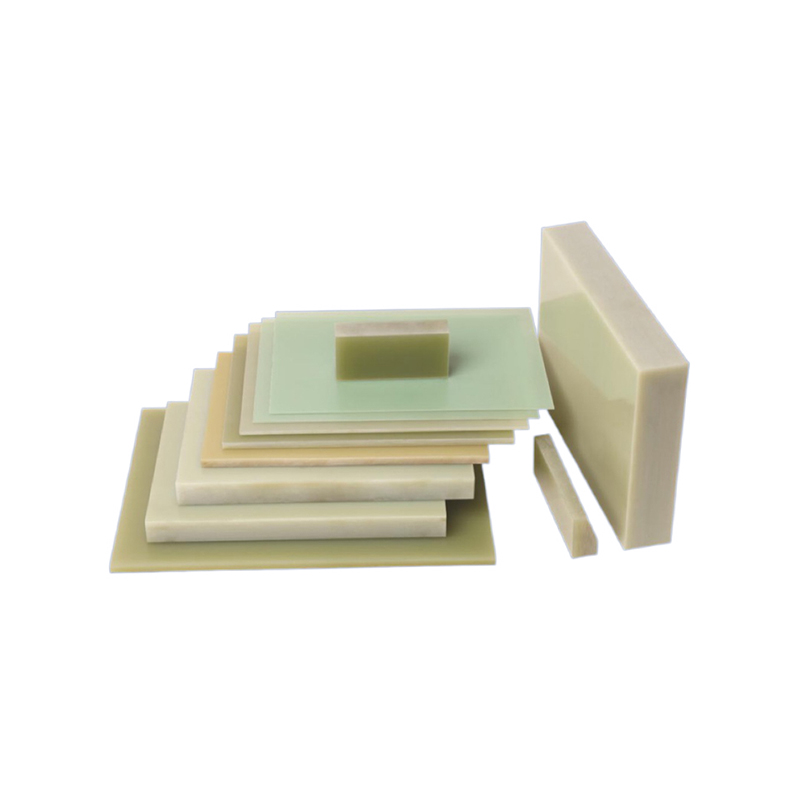

Ubukhulu obutholakalayo:0.30mm ~ 200mm

Usayizi weshidi otholakalayo:

1500mm*3000mm、1220mm*3000mm、1020mm*3000mm、1020mm*2440mm、1220mm*2440mm、1500mm*2440mm、1000mm*2000mm、1200mm*2000mm kanye nezinye izinhlobo zosayizi ezixoxiswane ngazo.

Ukuhlukaniswa kanye nohlobo lwamashidi e-Epgc

| Thayipha igama | Uhlelo lokusebenza kanye nesici | Isigaba sokushisa | |||

| I-D&F | I-GB/IEC | I-NEMA | abanye | ||

| DF201 | I-EPGC201 | G10 | I-Hgw 2372 | Kwemishini, imishini kagesi nama-electron. Ngamandla aphezulu ngaphansi kokushisa okuphakathi, ukumelana okuhle kakhulu kwe-arc kanye ne-PTI ephezulu kanye ne-CTI | B 130℃ |

| DF202 | I-EPGC202 | FR-4 | I-Hgw 2372.1,F881 | Kufana ne-EPGC201, ephethe i-flame retardant eshiwo. | B 130℃ |

| DF202A | --- | --- | --- | Kufana ne-DF202, kodwa kunamandla aphezulu okusebenza. | B 130℃ |

| DF203 | I-EPGC203 | G11 | Hgw2372.4 | Kwemishini, imishini kagesi kanye nama-electron. Ngamandla aphezulu ngaphansi kwezinga lokushisa eliphakathi nendawo | F 155℃ |

| DF204 | I-EPGC204 | FR-5 | I-Hgw 2372.2 | Kufana ne-DF203, ephethe i-flame retardant eshiwo. | F 155℃ |

| DF306 | I-EPGC306 | --- | DF336 | Ifana ne-DF203, inokumelana okuhle kakhulu kwelangabi, ukumelana ne-arc kanye ne-PTI ephezulu. | F 155℃ |

| DF306A | --- | --- | --- | Kufana ne-DF306, kodwa kunamandla aphezulu okusebenza. | F 155℃ |

| DF308 | I-EPGC308 | --- | --- | Kufana ne-DF203, kodwa kunokuzinza okungcono kokushisa. | Ukushisa okungu-180℃ |

Izidingo Zobuchwepheshe

Ukubukeka

Ubuso beshidi kumele bube bushelelezi futhi bube bushelelezi, bungabi namabhamuza omoya, imibimbi noma imifantu futhi bungabi nezinye iziphambeko ezincane njengokuklwebheka, ukufiphala, njll. Unqenqema lweshidi kumele luhlanzeke futhi lungabi namabala noma imifantu. Umbala kumele ufane kakhulu, kodwa amabala ambalwa ayavunyelwa.

Ubukhulu obujwayelekile kanye nokubekezelelanaIyunithi: mm

| Ukujiya okujwayelekile | Ukuphambuka | Ubukhulu be-Niminal | Ukuphambuka |

| 0.5,0.6 0.8,1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.15 +/-0.18 +/-0.21 +/-0.25 +/-0.30 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.85 +/-2.10 +/-2.45 +/-2.60 +/-2.80 |

| Amazwana: Kumashidi anobukhulu obungebona obujwayelekile angabhalwanga kuleli Thebula, ukuphambuka okuvunyelwe kufanele kufane nobukhulu obukhulu obulandelayo | |||

Ukuphambuka Kokugoba KwamashidiIyunithi: mm

| Ubukhulu | Ukuphambuka Kokugoba |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 |

Ukucutshungulwa kwemishini:

Amashidi kumele angabi nemifantu noma izinsalela uma kusetshenziswa imishini efana nokusaha, ukubhoboza, ukufaka i-lathing kanye nokugaya.

Izakhiwo Zomzimba, Zomshini Nezokushisa Ugesi

| Cha. | Izakhiwo | Iyunithi | I-EPGC201 | I-EPGC202 | I-EPGC203 | ||||

| Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | ||||

| 1 | Ukumuncwa kwamanzi (ishidi le-2mm) | mg | ≤20 | 8 | ≤20 | 9 | ≤20 | 9 | |

| 2 | Amandla aguquguqukayo | Esimweni esijwayelekile | I-MPa | ≥340 | 460 | ≥340 | 500 | ≥340 | 450 |

| (Ubude) | 155℃+/-2℃ | --- | --- | --- | --- | ≥170 | 240 | ||

| 3 | Amandla omthelela, ahambisana nama-lamination (i-Charpy, i-notch) | kJ/m2 | ≥33 | 53 | ≥33 | 51 | ≥33 | 50 | |

| 4 | Amandla kagesi, aqonde ngqo kuma-lamination (kuwoyela we-transformer ku-90℃+/-2℃) | kV/mm | ≥11.8 | 17 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Amandla kagesi, ahambisana nama-lamination (kuwoyela we-transformer ku-90℃+/-2℃) | kV | ≥35 | 48 | ≥35 | 45 | ≥35 | 45 | |

| 6 | Isici sokushabalalisa i-dielectric (1MHz) | --- | ≤0.04 | 0.02 | ≤0.04 | 0.02 | ≤0.04 | 0.021 | |

| 7 | I-dielectric constant (1MHz) | --- | ≤5.5 | 4.8 | ≤5.5 | 4.7 | ≤5.5 | 4.7 | |

| 8 | Ukumelana ne-arc | s | --- | --- | --- | 182 | --- | 182 | |

| 9 | Ukumelana nokulandelela ubufakazi (i-PTI) | V | --- | --- | --- | 600 | --- | 600 | |

| 10 | Ukumelana nokushisa ngemva kokucwiliswa emanzini | I-MΩ | ≥5.0x104 | 2.1 x107 | ≥5.0x104 | 1.5 x106 | ≥5.0x104 | 1.1 x107 | |

| 11 | Ukuvutha | Ibanga | --- | --- | V-0 | V-0 | --- | --- | |

| 12 | Inkomba Yokushisa (TI) | --- | ≥130 | ≥130 | ≥155 | ||||

| Cha. | Izakhiwo | Iyunithi | I-EPGC204 | I-EPGC306 | I-EPGC308 | ||||

| Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | Inani elijwayelekile | ||||

| 1 | Ukumuncwa kwamanzi (2mm) | mg | ≤20 | 11 | ≤20 | 8 | ≤20 | 9 | |

| 2 | Amandla aguquguqukayo | Esimweni esijwayelekile | I-MPa | ≥340 | 480 | ≥340 | 460 | ≥340 | 500 |

| (Lengwise) | 155℃+/-2℃ | ≥170 | 260 | ≥170 | 280 | --- | 270 | ||

| 3 | Amandla omthelela, ahambisana nama-lamination (i-Charpy, i-notch) | kJ/m2 | ≥33 | 51 | ≥33 | 53 | ≥33 | 52 | |

| 4 | Amandla kagesi, aqonde ngqo kuma-lamination (kuwoyela we-transformer ku-90℃+/-2℃) | kV/mm | ≥11.8 | 16 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Amandla kagesi, ahambisana nama-lamination (kuwoyela we-transformer ku-90℃+/-2℃) | kV | ≥35 | 45 | ≥35 | 48 | ≥35 | 45 | |

| 6 | Isici sokushabalalisa i-dielectric (1MHz) | --- | ≤0.04 | 0.018 | ≤0.04 | 0.02 | ≤0.04 | 0.02 | |

| 7 | I-dielectric constant (1MHz) | --- | ≤5.5 | 4.7 | ≤5.5 | 4.8 | ≤5.5 | 4.7 | |

| 8 | Ukumelana ne-arc | s | --- | --- | --- | 182 | --- | --- | |

| 9 | Ukumelana nokulandelela ubufakazi (i-PTI) | V | --- | --- | --- | 600 | --- | --- | |

| 10 | Ukumelana nokushisa ngemva kokucwiliswa emanzini | I-MΩ | ≥5.0x104 | 3.8 x106 | ≥5.0x104 | 1.8 x107 | ≥5.0x104 | 7.1 x106 | |

| 11 | Ukuvutha | Ibanga | V-0 | V-0 | V-0 | V-0 | --- | --- | |

| 12 | Inkomba Yokushisa (TI) | --- | ≥155 | ≥155 | ≥180 | ||||

Ukupakisha Nokugcina Isitoreji

Amashidi kufanele agcinwe endaweni lapho izinga lokushisa lingekho ngaphezu kuka-40℃, futhi abekwe ngokuvundlile epuletini lombhede elinokuphakama okungu-50mm noma ngaphezulu. Gcina kude nomlilo, ukushisa (imishini yokushisa) kanye nokukhanya kwelanga okuqondile. Isikhathi sokugcina samashidi siyizinyanga ezingu-18 kusukela ngosuku lokuphuma efektri. Uma isikhathi sokugcina singaphezu kwezinyanga ezingu-18, umkhiqizo ungasetshenziswa futhi ngemva kokuhlolwa ukuze uqinisekiswe.

Izimpawu Nezinyathelo Zokuqapha Zokusebenzisa

1 Umshini wokwakha kufanele uhambisane ne-JB/Z141-1979,Izindlela zomshini zokufaka izinto zokushisa ezifakwe i-laminate, ngoba amashidi anomehluko ongokwemvelo ngokwemfanelo kusuka kwensimbi.

2 Kufanele kusetshenziswe isivinini esiphezulu kanye nokujula okuncane kokusika lapho kucutshungulwa ngenxa yokushisa okubuthakathaka kwamashidi.

3 Ukushintshwa nokusikwa kwalo mkhiqizo kuzokhipha uthuli oluningi kanye nentuthu. Kufanele kuthathwe izinyathelo ezifanele ukuqinisekisa ukuthi amazinga othuli angaphakathi kwemingcele eyamukelekayo ngesikhathi sokusebenza. Kuyelulekwa ukuthi kungeniswe umoya wokukhipha umoya endaweni kanye nokusebenzisa imaski yothuli/yezinhlayiya ezifanele.

4 Amashidi athola umswakama ngemva komshini, kunconywa ukuthi ambozwe nge-insulating vanish.

Imishini Yokukhiqiza

Iphakheji Yamashidi e-EPGC