Ishidi Elinamanzi Le-GPO-3 (UPGM203) Le-Polyester Engagcwali

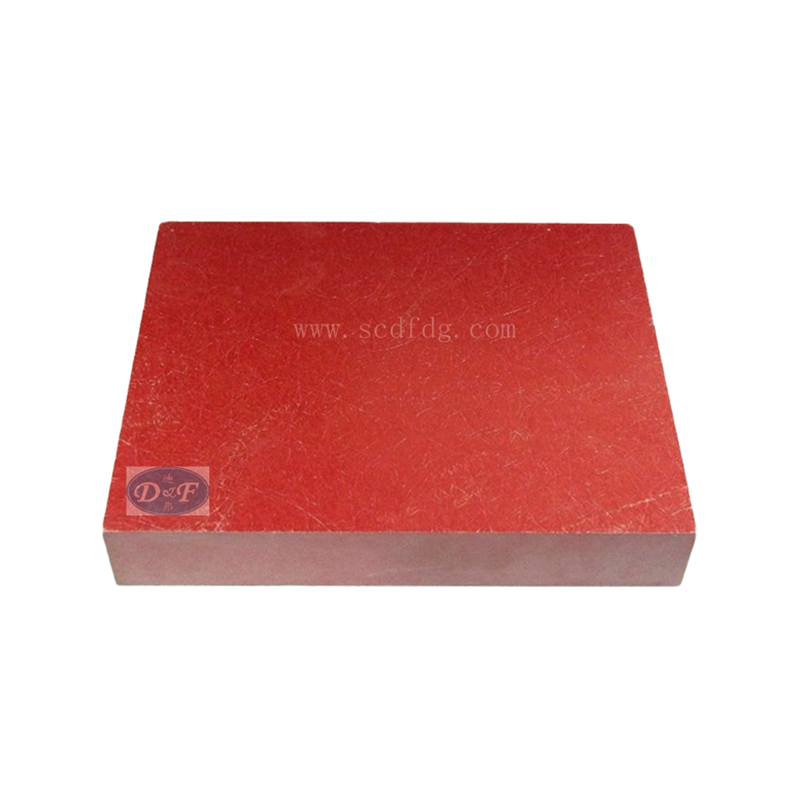

Ishidi Elibunjiwe le-GPO-3 (elibizwa nangokuthi i-GPO3, i-UPGM203) liqukethe umata wengilazi ongena-alkali ofakwe futhi oboshwe nge-resin ye-polyester engagcwalisiwe, futhi oqiniswe ngaphansi kokushisa okuphezulu kanye nokucindezela okuphezulu esikhumbeni. Linamandla okusebenza kahle, amandla aphezulu omshini, izakhiwo ezinhle ze-dielectric, ukumelana okuhle kokulandela umkhondo kanye nokumelana ne-arc. Linesitifiketi se-UL futhi liphumelele ukuhlolwa kwe-REACH kanye ne-RoHS, njll. Libizwa nangokuthi i-GPO-3 noma ishidi le-GPO3, i-GPO-3 noma ibhodi lokufaka i-GPO3.

Iyasebenza ekwenzeni izingxenye noma izingxenye zesakhiwo sokushisa nokusekelayo kuma-motor kagesi e-F-class, ama-transformer, amagiya okushintsha, ama-circuit breaker kanye nemishini kagesi. I-UPGM ingabunjwa ngqo ibe amaphrofayili ahlukene noma izingxenye zesakhiwo sokushisa.

Ububanzi bokujiya:2mm---60mm

Usayizi weshidi:1020mm *2010mm, 1000mm *2000mm, 1220mm *2440mm kanye nobunye ubukhulu noma/kanye nosayizi okuxoxiswane ngawo

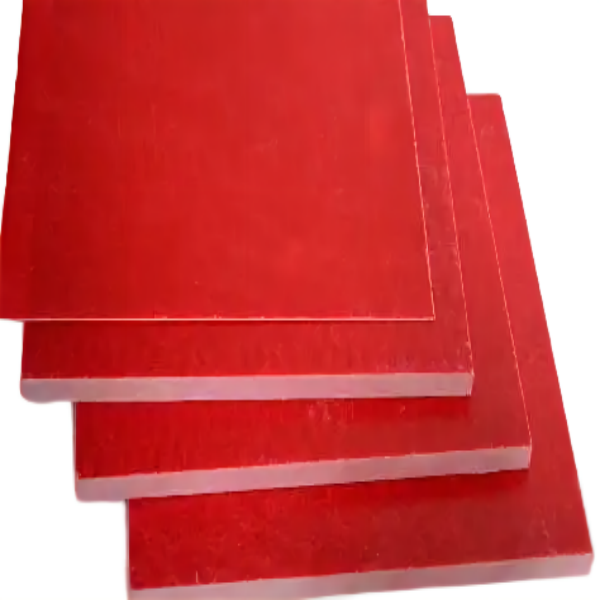

Umbala oyinhloko: obomvu, omhlophe noma eminye imibala exoxiswanayo

Ngaphandle kwamashidi agqitshwe nge-UPGM, siphinde sikhiqize futhi sinikeze amashidi e-EPGM 203, ubukhulu beshidi bufana nobe-GPO-3. Umbala uphuzi noma uluhlaza. Ngicela ungithinte ukuze uthole ulwazi olwengeziwe.

Izidingo Zobuchwepheshe

Ukubukeka

Ubuso bayo kufanele bube bushelelezi futhi bube bushelelezi, bungabi nama-blister, imibimbi noma imifantu futhi bungabi nezinye iziphambeko ezincane njengokuklwebheka, ukugoba kanye nemibala engalingani.

Okujwayelekileukucasuka kanyeukubekezelelana

| Ubukhulu obuqanjiwe (mm) | Ukubekezelelana okuvunyelwe (mm) | Ubukhulu obuqanjiwe (mm) | Ukubekezelelana okuvunyelwe (mm) | |

| 0.8 | +/-0.23 | 12 | +/-0.90 | |

| 1.0 | +/-0.23 | 14 | +/-1.00 | |

| 2.0 | +/-0.30 | 16 | +/-1.10 | |

| 3.0 | +/-0.35 | 20 | +/-1.30 | |

| 4.0 | +/-0.40 | 25 | +/-1.40 | |

| 5.0 | +/-0.55 | 30 | +/-1.45 | |

| 6.0 | +/-0.60 | 40 | +/-1.55 | |

| 8.0 | +/-0.70 | 50 | +/-1.75 | |

| 10.0 | +/-0.80 | 60 | +/-1.90 | |

| Qaphela: Kumashidi anobukhulu obungebona obujwayelekile angabhalwanga kuleli thebula, ukuphambuka okuvunyelwe kufanele kufane nobukhulu obukhulu obulandelayo. | ||||

Izakhiwo zomzimba, zemishini kanye nezegesi

| Izakhiwo | Iyunithi | Inani elijwayelekile | Inani elijwayelekile | Indlela yokuhlola | ||

| Ubuningi | g/cm3 | 1.65~1.95 | 1.8 | GB/T 1033.1-2008 | ||

| (indlela A) | ||||||

| Ukumuncwa kwamanzi, ubukhulu obungu-3mm | % | ≤ 0.2 | 0.16 | I-ASTM D790-03 | ||

| Amandla okugobeka, aqonde ngqo kuma-lamination (Ubude) | Esimweni esijwayelekile | I-MPa | ≥180 | 235 | I-ASTM D790-03 | |

| 130℃+/-2℃ | ≥100 | 144 | ||||

| I-modulus egobile, eqondile kuma-lamination (Ubude) | Esimweni esijwayelekile | I-MPa | - | 1.43 x 104 | ||

| 130℃+/-2℃ | - | 1.10 x 104 | ||||

| Amandla okugobeka, aqonde ngqo kuma-lamination (Ubude) | Ubude obude | I-MPa | ≥170 | 243 | GB/T 1449-2005 | |

| Ukuwela | ≥150 | 240 | ||||

| Amandla Omthelela, ahambisana nama-lamination | I-KJ/m2 | ≥40 | 83.1 | GB/T 1043.1-2008 | ||

| (Charpy, engakacaci) | ||||||

| Amandla Omthelela, ahambisana nama-lamination | J/m | - | 921 | I-ASTM D256-06 | ||

| (Izod, ihlutshiwe) | ||||||

| Amandla okudonsa | I-MPa | ≥150 | 165 | GB/T 1040.2-2006 | ||

| Imodulus yokuqina kwe-Tensile | I-MPa | ≥1.5x104 | 1.7 x 104 | |||

| Amandla okuqina, ahambisana nama-lamination | Ubude obude | I-MPa | ≥55 | 165 | GB/T1447-2005 | |

| Ukuwela | ≥55 | 168 | ||||

| Iqonde ngqo kuma-lamination | I-MPa | - | 230 | I-ASTM D695-10 | ||

| Amandla okucindezela | ||||||

| Amandla e-dielectric, aqonde ngqo kuma-laminations (kuwoyela we-transformer ongu-25# ku-90℃+/-2℃, ukuhlolwa kwesikhathi esifushane, i-electrode yesilinda engu-Φ25mm/Φ75mm) | I-KV/mm | ≥12 | 135 | IEC60243-1:2013 | ||

| I-voltage yokuqhekeka, ehambisana ne-animations (ku-25# transformer oil ku-90℃+/-2℃, ukuhlolwa kwesikhathi esifushane, i-electrode yepuleti ye-Φ130mm/Φ130mm) | KV | ≥35 | >100 | |||

| Imvume ehlobene (1MHz) | - | ≤ 4.8 | 4.54 | GB/T 1409-2006 | ||

| Isici sokushabalalisa i-dielectric (1MHz) | - | ≤ 0.03 | 1.49 x 10-2 | |||

| Ukumelana ne-Arc | s | ≥180 | 187 | GB/T 1411-2002 | ||

| Ukumelana nokulandelela | I-CTI | V | ≥600 | I-CTI 600 | ||

| I-overpass | I-GB/T 4207-2012 | |||||

| I-PTI | ≥600 | I-PTI 600 | ||||

| Ukumelana nokushisa | Esimweni esijwayelekile | Ω | ≥1.0x1013 | 5.4 x 1014 | I-GB/T 10064-2006 | |

| (Ama-electrode ephini elithambile) | Ngemva kwamahora angama-24 emanzini | ≥1.0x1012 | 2.5 x 1014 | |||

| Ukuvutha (Indlela Eqondile) | Ibanga | V-0 | V-0 | UL94-2013 | ||

| Ucingo olukhanyayo | - | - | I-GWIT: 960/3.0 | GB/T5169.13-2006 | ||

| Ubulukhuni beBarcol | - | ≥ 55 | 60 | I-ASTM D2583-07 | ||

Ukuhlolwa, Uphawu, Ukupakisha kanye Nokugcina

1) Iqoqo ngalinye kufanele lihlolwe ngaphambi kokuthunyelwa. Izinto zokuhlola ze-Routine Test kufanele zifake iSigaba 2.1, 2.2, kanye neSigaba 1 kanye neSigaba 3 seThebula 6 kuSigaba 2.3. Izinto kuSigaba 2.1, 2.2, kufanele zihlolwe ngayinye ngayinye.

2) Amashidi kufanele agcinwe endaweni lapho izinga lokushisa lingekho ngaphezu kuka-40℃, futhi abekwe ngokuvundlile epuletini lombhede elinokuphakama okungu-50mm noma ngaphezulu. Gcina kude nomlilo, ukushisa (imishini yokushisa) kanye nokukhanya kwelanga okuqondile. Isikhathi sokugcina samashidi siyizinyanga ezingu-18 kusukela ngosuku lokuphuma efektri. Uma isikhathi sokugcina singaphezu kwezinyanga ezingu-18, umkhiqizo ungasetshenziswa futhi ngemva kokuhlolwa ukuze uqinisekiswe.

Amazwi Nezinyathelo Zokuqapha Zokuphatha Nokusebenzisa

1) Kufanele kusetshenziswe isivinini esikhulu kanye nokujula okuncane kokusika lapho kucutshungulwa ngenxa yokushisa okubuthakathaka kwamashidi.

2) Ukushintshwa nokusikwa kwalo mkhiqizo kuzokhipha uthuli oluningi kanye nentuthu. Kufanele kuthathwe izinyathelo ezifanele ukuqinisekisa ukuthi amazinga othuli angaphakathi kwemingcele eyamukelekayo ngesikhathi sokusebenza. Kunconywa ukuthi kungeniswe umoya wokukhipha umoya endaweni kanye nokusebenzisa imaski yothuli/yezinhlayiya ezifanele.

Isitifiketi